Hot Tapping & Plugging For Petroleum Industry Power

Course overview

A process for putting connections on active equipment (pipelines, piping, storage tanks, vessels, etc.) is known as hot tapping. When drilling or making circular cuts on live equipment or pipe, the process is referred to as “hot tapping.” What does hot tapping serve as? In order to remove a section of piping while the processing system is still operating in order to repair or install new equipment there, this procedure is required.

The damaged portion must be repaired or replaced as a result of corrosion, a material flaw, etc. in order to install new parts, such as instruments, control valves, and pipe-branching, which will convey the fluid to another location. In order for the bypass to work and to reroute the flow of the pipeline fluid so that the isolated pipeline part is safe to remove or work in, at least two hot-tapped holes are used on either side of the isolable portion. These holes are used to insert inflatable plugs.

The procedure of hot tapping and isolating the affected portion of the area of interest by inserting at least two plugs—one on each side—through the tapped holes is used because stopping the flow of gas in large installations and businesses has significant economic effects on both the national and international levels.

The possibility for really major catastrophes like fire and explosion makes this entire operation extremely dangerous. Therefore, this task must only be performed by trained employees and supervisors under the careful supervision of technical managers.

Participants in this Training Bee training course will leave with a thorough understanding of “Hot Tapping Gas Pipeline and Plugging Procedure in Petroleum Industry.”

Introduction

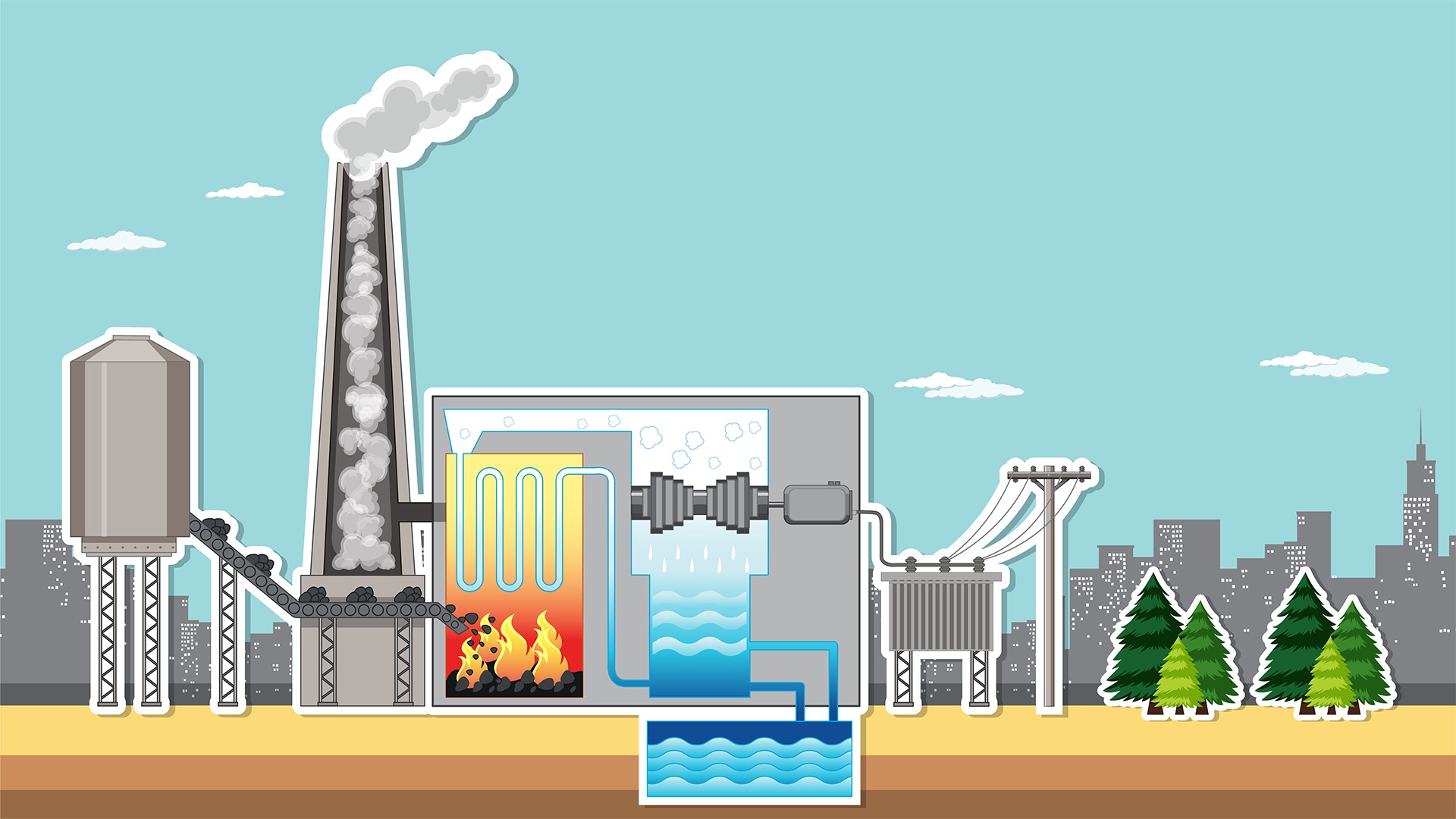

The petroleum sector is crucial to meeting the world’s energy requirements, and its core consists of extensive pipeline networks that move gas and oil across long distances. To guarantee a consistent supply of energy resources, it is crucial to maintain and grow these networks. In order to enable pipeline maintenance, repairs, and alterations while maintaining the uninterrupted flow of oil and gas, hot tapping and plugging processes are essential techniques employed in the petroleum sector.

The crucial importance that hot tapping and plugging operations play in the petroleum sector is explained in this introduction. They stand for the fine line that must be drawn in the field of energy transportation between preserving operational effectiveness, guaranteeing safety, and upholding environmental responsibility. For these procedures to be implemented successfully, extensive training, regulatory compliance, and a dedication to best practices are essential.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

Learning Objectives

Upon completing Hot Tapping Gas Pipeline and Plugging Procedure in Petroleum Industry, participants will be able to:

- Recognize the ideas of hot tapping and plugging.

- Recognize the benefits and drawbacks of hot tapping and plugging in the gas and petroleum industries Understand the hot tapping and plugging methods

- Recognize the risks associated with hot tapping and plugging

- Do a risk assessment and become knowledgeable on how to handle various high-risk situations.

- Plan the actions necessary for hot tapping and plugging.

- Examine a number of severe accidents that occurred when hot tapping and plugging in the gas and petroleum industries.

- Take part in resolving the problems and case studies related to them.

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

- Case studies – Participants will be presented with realistic scenarios and case studies that demonstrate effective strategies related to the topic. These activities will encourage participants to think critically and apply their knowledge to real-life situations.

Training Medium

This Hot Tapping Gas Pipeline and Plugging Procedure in Petroleum Industry training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- Why is hot tapping utilized in the petroleum business, and what does it entail?

- Can you describe the possible dangers of hot tapping a gas pipeline?

- Describe the common processes involved in a gas pipeline hot tapping technique.

- What kinds of tools and equipment are frequently employed in hot tapping operations?

- How can the environment and staff be kept safe when a hot tapping process is being done?

- What factors are most important to take into account when deciding where to install a gas pipeline hot tap?

- What does a plugging process in the context of hot tapping accomplish? When is it required?

- Describe the procedures and equipment needed to safely plug a pipeline.

Course Modules

This Hot Tapping Gas Pipeline and Plugging Procedure in Petroleum Industry covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – HOT TAPPING AND PLUGGING IDEAS

- Pipeline for gas

- Crude oil pipeline

- There may be further uses for hop tapping and plugging.

- Warm-tap plugging

Module 2 – The benefits and drawbacks of hot tapping and plumbing

- Customer satisfaction with significant cost savings and speedy outcomes

- Fire and explosion risks

- Risks of workplace fatalities and serious injuries if plans and operations are not carried out safely

Module 3 – PREPARE FOR HOT TAPPING PROCEDURE

- Management Permission

- Details of the metal that will be tapped

- The fluid’s physical and chemical characteristics will be used.

- Calculations made in accordance with the relevant local regulations, standards, and codes of practice

- Examination and testing of the equipment’s exterior condition before tapping

- Design and fabrication of the stub bases at the potential tapping locations

Module 4 – EXECUTION OF HOT TAPPING PROCEDURE

- Check for increases in process pressure and temperature during the hot tapping operation, and if possible, try to significantly lower them. gauged parameter monitoring

- Use fillet welds to join the reinforcement and stub. after-weld examination

- Keeping the product flowing through the pipeline while welding to prevent heat buildup

- On the flange of the welded stub through which the tapped hole is to be formed, attach the isolation valve (side-assembly).

Module 5 – THE SETUP OF A BYPASS LINE

- Create two hot tapping connections on either side of the pipeline’s impacted section.

- Attach the ready-made bypass line.

- Check for leaks, integrity, and safety

- Open the valves at both ends to open the bypass line.

Module 6 – MAKE PLUGGING PORTS

- Create two hot tapping connections within the bypass segment and on either side of the impacted area.

- Replace the hot tapping machine above the isolation valves with the plug insertion assembly (i.e., line stop actuator).

- Check for leaks, integrity, and safety

Module 7 – PLUGGING TO ISOLATE THE AFFECTED AREA IS A PROCEDURE

- By opening the isolation valves, place the plugs (line stops/stopples) into the tapped holes.

- To ensure gas sealing, inflate or activate the seals around the cylindrical plugs’ perimeter.

- Check for leaks, integrity, and safety

- Keep an eye on the environment to make sure there are no gas leaks past the plugs.

Module 8 – REMOVING AND REPLACING THE AFFECTED AREA

- In order to rule out a major continuous gas leak into the afflicted region as part of emergency safety preparation, pilot or test drill lightly on one side of the affected piece.

- Suck out any remaining gas from the damaged area.

- Complete the incision, then take out the damaged area.

- Welding the replacement pipe into place while doing integrity checks

Module 9 – CLOSE THE BYPASS AND OPEN THE MAINLINE

- Deflate and deactivate the plug seals gradually and cautiously.

- Pull back the plugs cautiously and slowly.

- Put the plug port isolation valves closed.

- After removing the plugging components on both sides of the impacted area, install blinds atop the flanged stubs.

- Close the isolation valves on the bypass line slowly and gently.

Module 10 – INDUSTRIAL SERIOUS INCIDENTS WHILE HOT TAPPING AND PLUGGING

- Analysis of incidents

- Problem analysis, root cause analysis, and remedial action

- Participants’ presentations of solutions.

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- Why is hot tapping utilized in the petroleum business, and what does it entail? Give a succinct justification.

- List the essential phases in a gas pipeline hot tapping method.

- Describe a plugging procedure’s function and significance in the context of hot tapping.

- What possible dangers and risks are there while hot tapping a gas pipeline, and how can they be reduced?

- When working with high-pressure gas pipes, what safety steps and safeguards should be taken?

- What kinds of tools and equipment are frequently utilized while hot tapping and plugging, and how are they employed?

- What variables should be taken into account when choosing a location for a hot tap on a gas pipeline?

Lessons Learned

Safety comes first: The main takeaway from this course is that when dealing with gas pipelines, safety should always come first. Hot tapping and plugging processes must be carried out with safety precautions in mind at every stage to avoid mishaps and safeguard both workers and the environment.

Thorough Planning is Crucial: When performing hot tapping and plugging operations, careful planning is essential. Location, apparatus, supplies, and emergency response plans should all be carefully taken into account to minimize risks and guarantee success.

Regulation Compliance Is Important: Industry regulations and standards must be followed at all times. To prevent legal problems and to uphold safety and environmental standards, it is crucial to comprehend and abide by local, national, and international legislation.

Continuous Education and Training: The petroleum business is always changing. Personnel engaged in hot tapping and plugging processes should participate in continual training and education to stay current with the latest technology and best practices in order to be safe and effective.

Teamwork and Communication: During these procedures, effective teamwork and communication are essential. Clare communication can avoid misunderstandings and errors, and everyone should be informed of their duties and responsibilities.

Emergency Planning: Unexpected incidents can occur. A key lesson is to constantly be ready for emergencies, to know how to react, and to have the tools and procedures in place to handle unforeseen circumstances.