Oil Well Cementing: Advanced Techniques

Course overview

What is the job of an oil well cementing technician?

The engineer and technician in charge of cementing oil wells is in charge of creating the cementing procedure, plugging the well, and determining the equipment needed for cementing oil wells utilizing a range of techniques and procedures. There are some oil fields where leaks must be sealed with cement to prevent further deterioration brought on by well aging. Since cementing and plugging oil wells is a crucial task, only personnel with the necessary training can carry it out carefully and safely.

With the help of Training Bee’ oil well plugging and cementing engineering course, you will gain the knowledge and skills necessary to comprehend the cementing operation and procedures, including cementing calculations, materials to be used, and procedures to be followed in accordance with industry guidelines and regulations. Current best practices and certain process uncertainties will be covered in this Training Bee course.

How is the volume of concrete calculated?

Because there are many dangers associated with well cementing, careful planning and efficient cost control must be carried out by engineers. One of the main concerns is how to work efficiently while cutting costs. It is necessary to recognize and create effective processes for cementing oil wells and pipe systems. During the cementing process, the engineering of oil well plugging and cementing investigates novel and unusual techniques. The study of cementing procedures for oil wells is covered in this course. Through this training, you will have the chance to improve your abilities and assist the organization in carrying out the cementing of oil wells.

Introduction

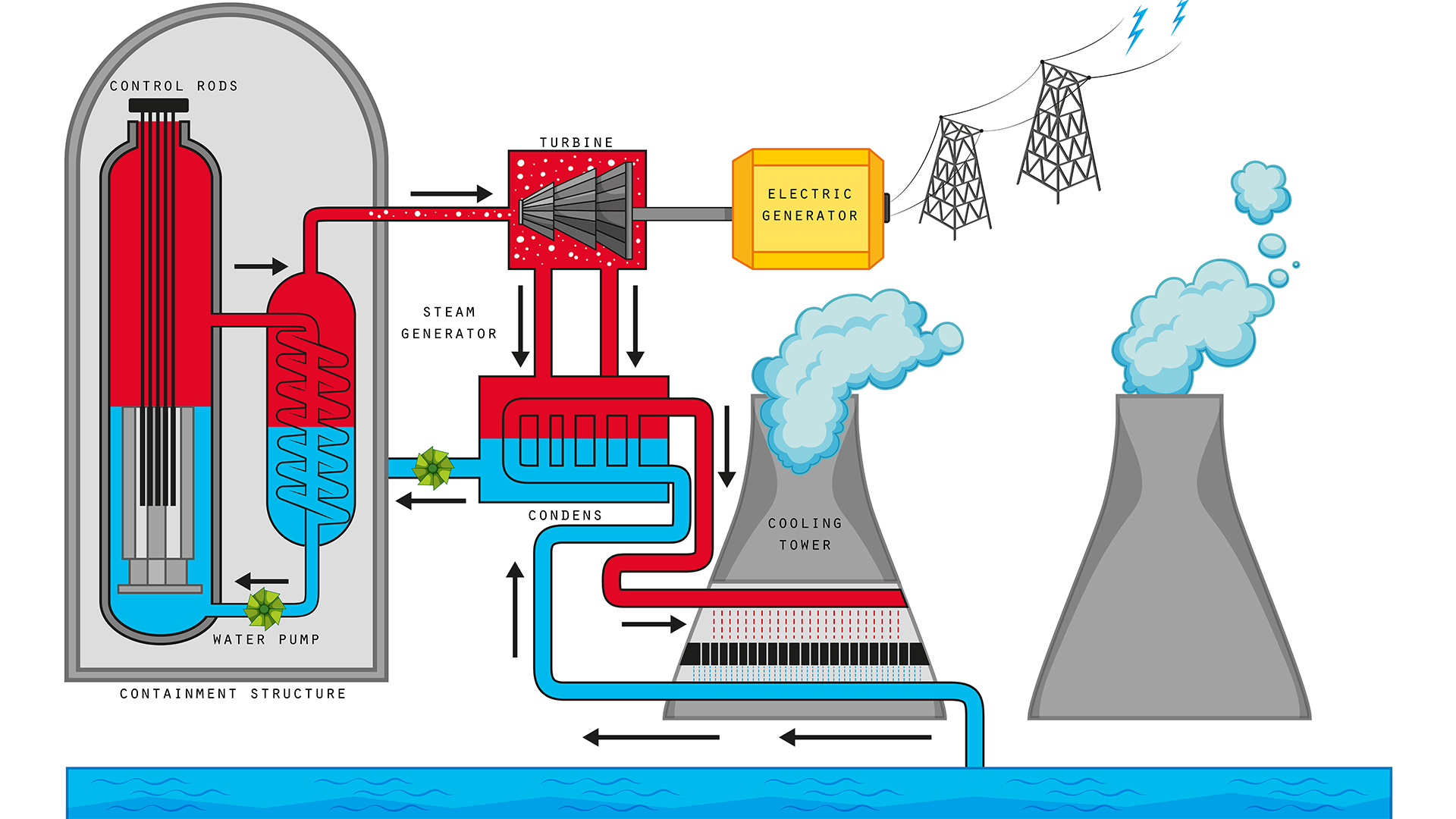

In the oil and gas sector, cementing oil wells is a crucial and intricate procedure that is essential to maintaining the integrity and security of these wells. An overview of the essential elements and ideas surrounding oil well cementing, including calculations, procedures, tools, and technologies, is given in this introduction.

In conclusion, it is critical for professionals working in the oil and gas sector to comprehend the nuances of oil well cementing calculations, procedures, tools, and technology. This information is essential for safeguarding the environment, preserving the integrity of oil and gas wells, and guaranteeing the security of wellsite operations. The course’s next lectures will go into further detail about these elements, giving participants the know-how and abilities needed for an oil well cementing job successfully done.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

Learning Objectives

Upon completing Oil Well Cementing Calculations, Process, Equipment and Technologies, participants will be able to:

- Gaining knowledge about every facet of cementing activity

- To impart cementing of oil well expertise and abilities

- To offer insight into a range of significant issues and ideas putting cement in oil wells

- Making precise cementing process calculations

- Effective techniques for sealing oil wells

- To familiarize oneself with industry standards and requirements

- The capacity and potential to address typical issues in cementing operations

- The necessary understanding of laws and rules’ guidelines

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Project-based learning

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

Training Medium

This Oil Well Cementing Calculations, Process, Equipment and Technologies training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- Why is oil well cementing an important procedure in the oil and gas sector, and what does it entail?

- What are the primary goals of cementing in an oil well, and how do these goals connect to zonal isolation and well integrity?

- What are some popular forms of oil well cement used in the business, what are their names, a brief description of them, and when are they usually applied?

- Have you ever made calculations for cement, such as those involving slurry density, volume, or thickening time? If so, kindly give some instances.

- How can zonal isolation support both environmental protection and well integrity, and why is it vital in oil well cementing?

Course Modules

This Oil Well Cementing Calculations, Process, Equipment and Technologies covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – An overview of the oil well cementing procedure

- Knowledge of the cementing procedure

- First Off Technologies for cementing oil wells

- Leak prevention and cementing

Module 2 – Cementation procedure

- Investigation of various cementing methods

- Cementing techniques and technologies

- First cementing

- Evaluation and computation of cementing

Module 3 – Organizing and transferring gas from oil wells

- Preparing to cement a well

- Migration and leaking of gases

- Control of gas

- Parts of a well barrier

Module 4 – Instruments and cementing technique

- Frequently used equipment

- Varieties of well cementing techniques

- Innovative methods and technologies

Module 5 – Best practices and risk assessment

- Evaluation of cementing risks

- Risk mitigation

- Best cementing techniques

Module 6 – Evaluation of cement and casing

- Casing assessment methods

- Methods for evaluating cement

- Modern methods and remedial cement

Module 7 – Laws, rules, and regulations

- Rules governing the cementation of oil wells

- Laws across different nations

- Environmental issues and regulations

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- List the essential phases in the basic cementing process, from preparing the slurry to placing and displacing the cement.

- Describe typical difficulties or problems that may occur throughout the cementing process and how they might be resolved or avoided.

- Talk about the safety precautions and guidelines that need to be followed when cementing oil wells in order to protect both the environment and the people involved.

- Provide an overview of any new developments in oil well cementing that you learned about throughout the course, along with an explanation of their possible benefits.

- Describe how environmental and regulatory factors affect oil well cementing operations domestically or globally, and talk about the industry’s obligation to comply.

- Provide a brief overview of the testing protocols and quality assurance techniques used to guarantee that cement sheaths in wellbores are operating as intended.

Lessons Learned

The significance of well integrity should have become clear to all attendees, as well as the vital role that well integrity plays in the oil and gas sector. They are aware that cementing oil wells is essential to maintaining well integrity and zonal isolation, stopping gas and oil leaks, and safeguarding the environment.

Cement Types and Selection: Participants should be adept at determining which type of cement is best for a given set of well conditions and comprehend how the performance of the cement sheath is impacted by varying cement compositions.

Calculations for cementing: Participants in the course ought to have acquired the abilities and information necessary to carry out precise calculations for cementing, such as those for slurry density, volume, and thickening time.

Tools and Equipment: Participants should be well aware of the tools and equipment used in oil well cementing, as well as how they work. They understand how crucial it is to choose and maintain equipment properly.

Mastery of Zonal Isolation: Participants should be able to avoid communication between various well zones, ensure wellbore stability, and effectively achieve zonal isolation using appropriate cementing techniques.

Safety Culture: Participants’ oil well cementing procedures should be deeply rooted in safety. They are aware of the possible risks associated with their work and the need of following safety procedures to safeguard both the environment and the workforce.

Regulatory Compliance: Participants are knowledgeable about the environmental and regulatory factors governing the cementing of oil wells. They understand the importance of following the law and practicing good environmental management.