Secrets To LPG Terminal Design & Plant Operations

Course overview

The light hydrocarbon components that make up liquefied petroleum gas, or LPG, are a blend of propane and butane. Since it is a non-toxic but extremely combustible gas, LPG terminals must be carefully planned to eliminate any risks brought on by the gas’s physical characteristics.

LPG must be handled carefully, thus all plant activities must be done in strict accordance with global standards and with the utmost safety.

To accept, store, mix, and distribute LPG, LPG terminals are designed. Safety and planning are essential to the effectiveness of plant operations, especially given the scale of these activities.

You will gain comprehensive understanding of LPG terminal designs and the security of activities carried out there thanks to this Trainee Bee.

With the knowledge and talents you will get from this course, you may work in any area of LPG operations, opening up more options for professional advancement.

Introduction

The design and operation of a Liquefied Petroleum Gas (LPG) Terminal is a complex process that involves many safety considerations. It is important that the terminal operators, designers and managers understand the potential hazards associated with the terminal and develop a safety plan that ensures the safety of the workers, equipment and the environment. The design of an LPG terminal must consider the location, size, type of product being stored, and the operational requirements. It is important to consider the weather conditions in the area, the type of land available, the potential for fire, and the risk of explosions.

The design should also include provisions for emergency response, access, and security. In addition to the physical design of the terminal, the operators must develop safety plans and procedures to ensure that the terminal is operated safely. This includes the development of a risk assessment and emergency response plan, safety training and the use of safety equipment. Regular inspections should be conducted to ensure that the terminal is operating safely and that equipment is functioning properly.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

Learning Objectives

Upon completing Secrets to LPG Terminal Design & Plant Operations, participants will be able to:

- Examine and alter present terminal designs and layouts for your firm to meet with needed standards by properly understanding LPG terminal operations and design requirements.

- Verify terminal operations for adherence to safety standards.

- instructing other experts in crucial areas of terminal design and operational safety

- contribute to the development and reputation of the company by strictly adhering to safety measures

- Utilize cutting-edge tools and technology in your operations to raise safety standards and lower the likelihood of workplace hazards

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

- Group discussions – The course will incorporate group discussions and debates to encourage active participation and collaboration.

- Case studies – Participants will be presented with realistic scenarios and case studies that demonstrate effective strategies related to the topic. These activities will encourage participants to think critically and apply their knowledge to real-life situations.

Training Medium

This Secrets to LPG Terminal Design & Plant Operations training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hour’s crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- What safety regulations should be taken into account when designing and operating an LPG terminal?

- What safety considerations should be made when storing LPG?

- What is the safety hazards associated with loading and unloading of LPG?

- What safety protocols should be followed when handling LPG tanks and equipment?

- How can safety be improved in the areas of maintenance, storage, and transportation of LPG?

- What potential fire hazards should be taken into account when designing and running an LPG terminal?

Course Modules

This Secret to LPG Terminal Design & Plant Operations covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – Summary of LPG

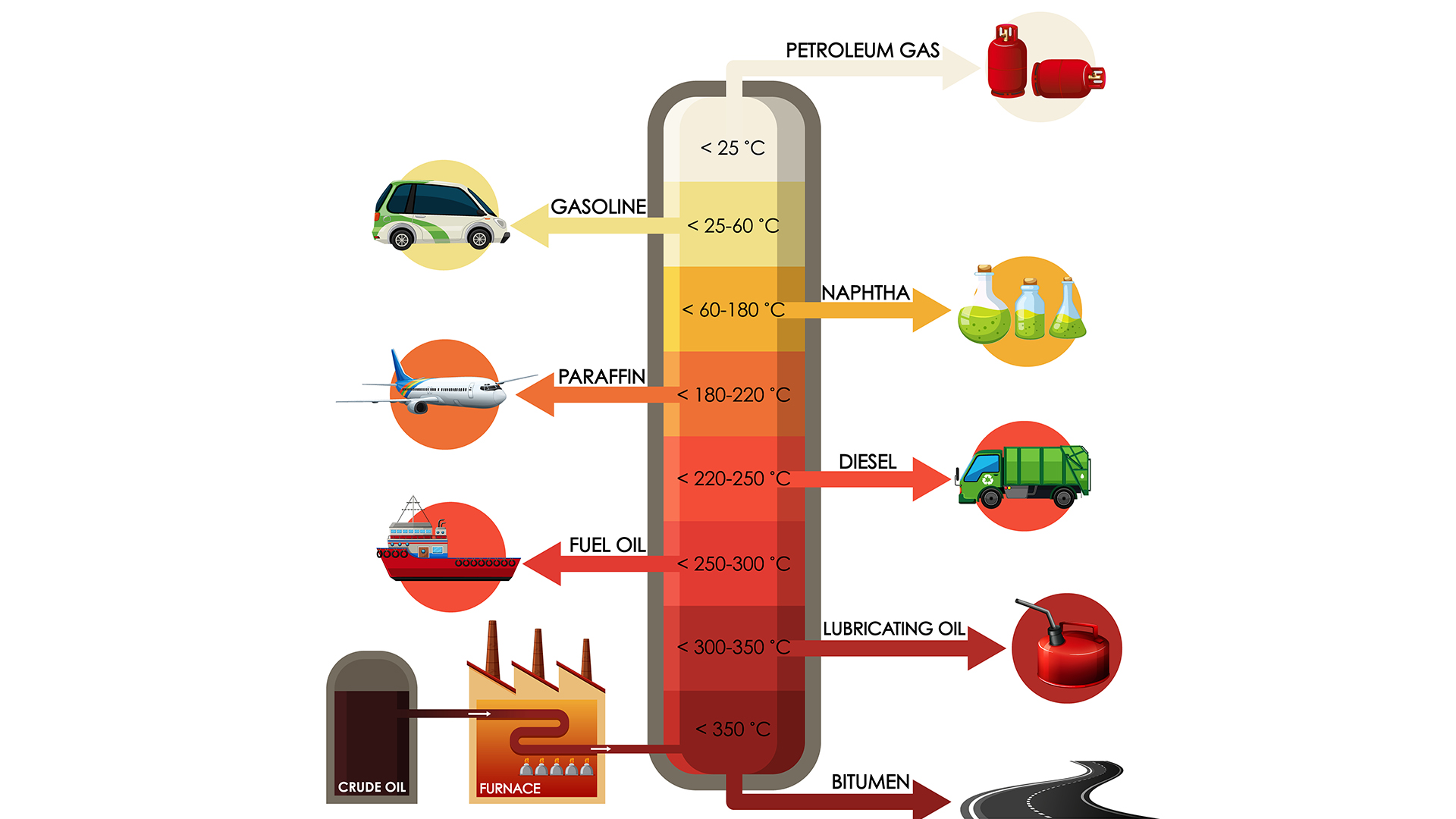

- Composition

- Physical features and attributes:

- Density

- pressure of vapor

- Flammability

- Combustion

- common uses

- Both benefits and drawbacks

Module 2 – LPG Terminal Design Determinants

- Total storage capacity Minimum LPG shipping amount

- The distribution system for repurchasing and reselling large amounts of LPG

- simplicity of use and upkeep

Module 3 – LPG Terminal Safety Features

- sprinkler system and firefighting equipment

- method for detecting gas leaks

- system for managing assets

- design with high integrity

- thorough emergency systems

Module 4 – Layout and Location of LPG Storage Tanks

- Location Screening

- flammable substance

- Horizontal movement

- numerous tanks

- electric cables in the air

Module 5 – Design of LPG Tank

- code of design

- circumstances for design

- prevention of corrosion

- Supports for tanks Markings and labels for tanks

Module 6 – Armour for tanks

- Valve pressure relief

- connections to drains

- content metric

- Disposal valves

- establishing connections

Module 7 – Decommissioning and Commissioning of Tanks

- LP gas vapor purging with inert gas purging

- Purging with water Evacuation

- Decommissioning initiatives and actions

- Leak Detection

Module 8 – Examining Additional Equipment

- mechanism of product transfer

- Regulation of vaporizers and electrostatic shielding

- electrical apparatus

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- What safety considerations should be taken into account when designing and constructing an LPG terminal?

- What safety protocols should be in place for personnel operating an LPG terminal?

- What safety equipment is necessary to ensure safe operations at an LPG terminal?

- What procedures should be followed in the event of an emergency at an LPG terminal?

- What personnel training are necessary for safe operations at an LPG terminal?

- What safety measures should be taken to prevent incidents related to human error at an LPG terminal?

Lessons Learned

The key lesson learned from the LPG Terminal Design and Plant Operations Safety training course is that safety comes first in all aspects of LPG terminal design and operations. Employees must be trained in proper safety practices, and all equipment must be regularly inspected and maintained to ensure the safety of personnel and the public. Proper safety measures should be taken at every stage of the process, from the initial design of the facility to the day-to-day operations. By ensuring that the proper safety protocols are followed, LPG terminals can minimize the risk of accidents and protect everyone involved in the process.

“Your staff will be better equipped to function safely and productively in any hazardous setting if they have taken the LPG Terminal Design and Plant Operations Safety training course.”