Secrets To Successful Petroleum Storage

Course overview

What exactly is petroleum storage?

The extraction of products is not the only significant process in the petroleum resource production cycle. Petroleum storage is critical to its supply since an inefficient system for storing petroleum resources and products can result in unfathomable losses to producers, citizens, communities, and the country. It could also signal that the area where such poor storage is located is in imminent danger. As a result, it is critical to guarantee that the storage facilities have a secure security system that cannot be easily breached. This will prevent unauthorized and excessive entrance into the storage facility. These safeguards will help to avoid damage to storage equipment and oil theft, among other things.

How petroleum products are kept safe?

The significance of proper petroleum storage cannot be overstated. This comes with a general understanding of the economic significance of petroleum. Those who take these courses will learn more about the best procedures for operating petroleum storage depots. This comprises the many safety precautions that must be taken before to, during, and after the storage of petroleum products. Participants will be exposed to avoidable hazards at the storage depot, such as fire accidents, as well as preventative and reactionary actions to mitigate the harm that may follow from such an outbreak, if one occurs.

Introduction

Welcome to “Best Practice in Petroleum Storage Depot Operations.” This thorough training is designed to give industry professionals with the information and skills required to manage petroleum storage depots effectively and sustainably. Petroleum product storage must be safe and efficient in order to ensure product quality, environmental protection, and the safety of workers and communities.

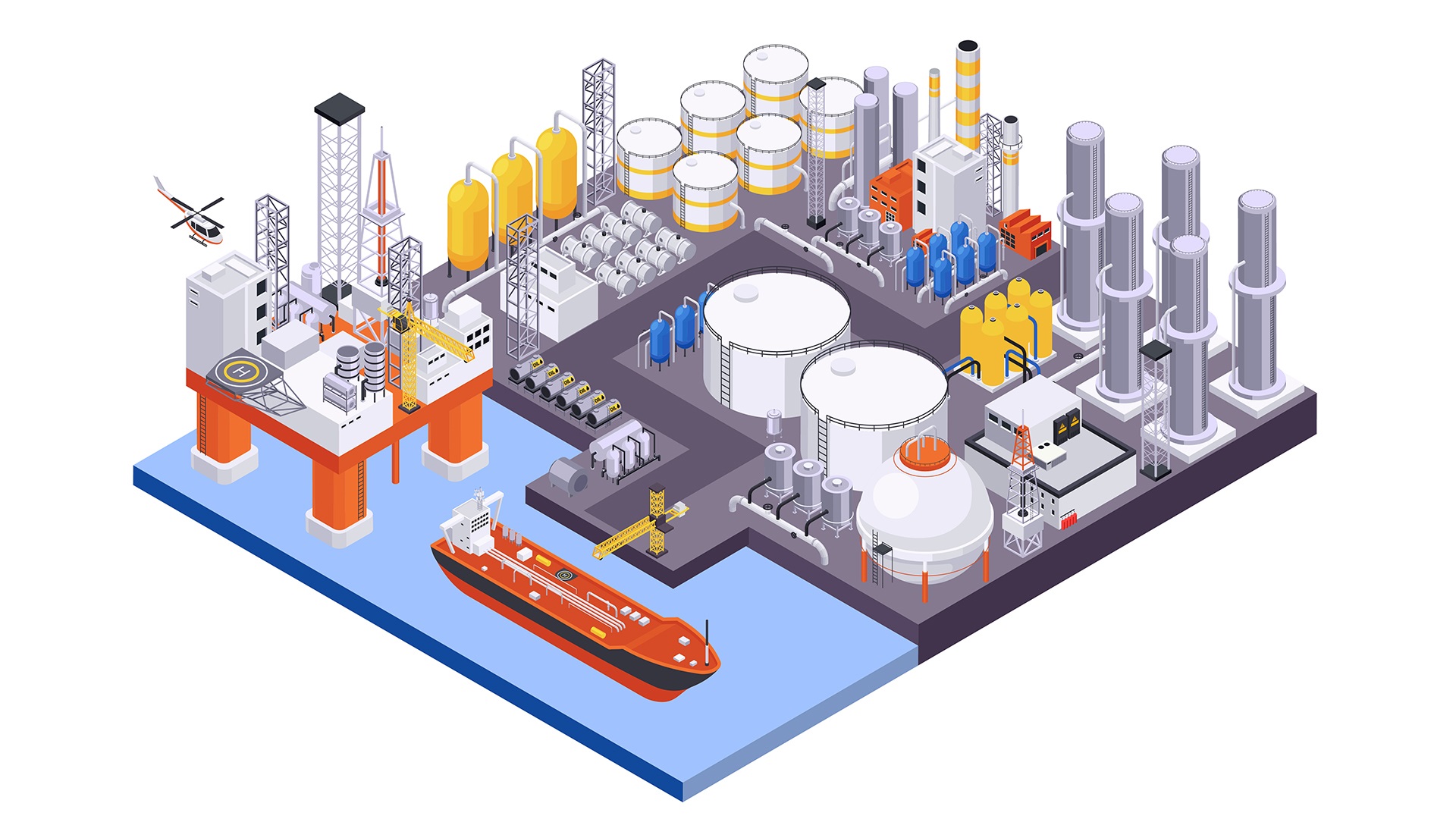

Petroleum storage depots play an important part in the oil and gas supply chain. They are key nodes for the storage and delivery of a wide range of petroleum products, from crude oil to refined fuels and chemicals. To maintain safety, compliance, and environmental responsibility, successful operations in these facilities necessitate a thorough awareness of best practices.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

This course has no necessary prerequisites. It is intended for people with varied levels of experience in petroleum storage depot operations.

We are excited to embark on this educational adventure with you. We will investigate best practices in petroleum storage depot management together, providing you with the information and skills needed to run these facilities efficiently, ethically, and safely. Let’s get started on the road to depot operations excellence.

Learning Objectives

Upon completing Best Practices in Petroleum Storage Depot Operations, participants will be able to:

- Learn about the best practices in petroleum storage depot operations.

- Understand the suitable storage facilities and structural dimensions that should be used based on the various types of petroleum products.

- Recognize the safety procedures and mechanisms that must always be in place.

- Understand the various petroleum storage terms.

- Understand the many engineering procedures used to ensure the storage depot’s optimal operation and to prevent or minimize the loss of petroleum resources.

- Understand the health consequences of incorrect or ineffective petroleum resource and product storage at a depot.

- Know the routine inspections performed by highly qualified maintenance officers to ensure the storage depot’s smooth and safe functioning.

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Project-based learning

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

Training Medium

This Best Practices in Petroleum Storage Depot Operations training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- Define the purpose of a petroleum storage depot in the oil and gas industry.

- Distinguish between above-ground and below-ground storage tanks.

- List some of the most important safety and environmental laws that govern petroleum storage depot operations.

- Explain why regulatory compliance is so important in storage depot operations.

- Name the many types of petroleum products that are routinely held in storage depots.

- Describe the distinct storage needs and challenges of various petroleum products.

- Discuss the essential principles of petroleum tank design and construction.

- Explain the significance of tank materials, sizes, and capacities.

Course Modules

This Best Practices in Petroleum Storage Depot Operations covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – Concept Meaning and Definition

- What exactly is petroleum storage?

- How critical is petroleum storage?

- What variables should be addressed when locating petroleum storage depots?

- What are the difficulties associated with petroleum storage?

Module 2 – Chemical and Petroleum Product Storage Types

- Vertical with a brittle roof-to-shell seam

- Horizontal or vertical emergency relief venting tanks

- Tools for measuring and gauging depth, temperature, and level, among other things.

- Methods of maintenance and inspection

- Painting as a corrosion prevention strategy for tanks

Module 3 – The Effects of Different Storage Methods

- Oil storage, practices, and environmental concerns.

- The Connection between Good Oil Storage Practices and Healthcare.

- The Effects of Proper Petroleum Storage Practices on the Country’s Gross Domestic Product (GDP).

- Profit increases as a result of best petroleum depot practices.

Module 4 – Bulk Petroleum Storage Depot Planning

- Large Storage Tank Design, Structure, and Construction

- Depot Construction Topography and Soil Structure

- Above-ground Tank Venting at a Normal Level

- Pollution Prevention Through Emergency Venting Spillage Control

Module 5 – Building Types and Specifications in Petroleum Depots

- Administrative buildings

- Facilities for operation

- Service structures

- Power Generation

- Boiler rooms

Module 6 – Various Operations at Petroleum Storage Depots

- The Bulk Cargo Delivery Exchange to Tankers.

- Rail tanker loading and unloading.

- Road transport vehicle loading and unloading.

- A suitable environment for transfer operations.

- Quantity Calculation

Module 7 – Fire Prevention and Control in Depots

- Sources of ignition.

- Control over access.

- Firefighting equipment is available.

- Extinguishers, water, and fire hoses are all required.

Module 8 – Personnel Protection and Welfare at Petroleum Storage Depots

- Measures for Safety and Protection

- Petroleum Product Contact and First Aid

- The presence of a hospital on the premises

- Availability of qualified medical personnel

Module 9 – Petroleum Storage Depot Maintenance and Expansion

- Procedure for Risk Assessment Repairs and Alterations

- Availability and Usability of Equipment

- Tanks, vessels, and so on.

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- Define the main functions of a petroleum storage depot and how they help the oil and gas supply chain.

- Discuss the differences and applications of above-ground and below-ground storage tanks.

- Explain how safety and environmental standards affect the operations of petroleum storage depots.

- Give instances of best practices in safety and the environment that you have learned and implemented.

- List numerous different types of petroleum products that are commonly held at a storage facility.

- Describe the special storage requirements and challenges of a particular petroleum product.

- Summarize the most important factors to consider while designing and building tanks for petroleum storage facilities.

- Discuss how tank material, size, and capacity play a role in storage depot operations.

Lessons Learned

Understanding the importance of adhering to safety and environmental standards is critical to maintaining the integrity of petroleum storage depot operations and protecting the environment and public safety.

The highest priority is safety: Recognizing the importance of safety measures, emergency response plans, and a proactive safety culture in preventing accidents and assuring staff safety.

Environmental accountability: Recognizing the importance of environmental stewardship by putting in place procedures to prevent spills, leaks, and pollution while reducing the environmental effect of depot activities.

Quality control is essential: Understanding that maintaining product quality and controlling contamination are critical to sustaining the value and marketability of stored petroleum products.

Tank Design and Maintenance: Recognizing the need of good tank design, building, inspection, and maintenance methods in guaranteeing storage tank longevity and safety.

Inventory Management Is Important: Recognizing the importance of excellent inventory management in improving operations, lowering losses, and maintaining product availability.

Understanding the need of being prepared for emergency events, such as spill response, fires, and equipment breakdowns, in order to reduce damage and safeguard personnel.

Recognizing that the field of petroleum storage depot operations is dynamic and that experts should seek chances for development and efficiency on a continuous basis.