Supercharge Your Oil & Gas Production & Facilities Operations Skills

Course overview

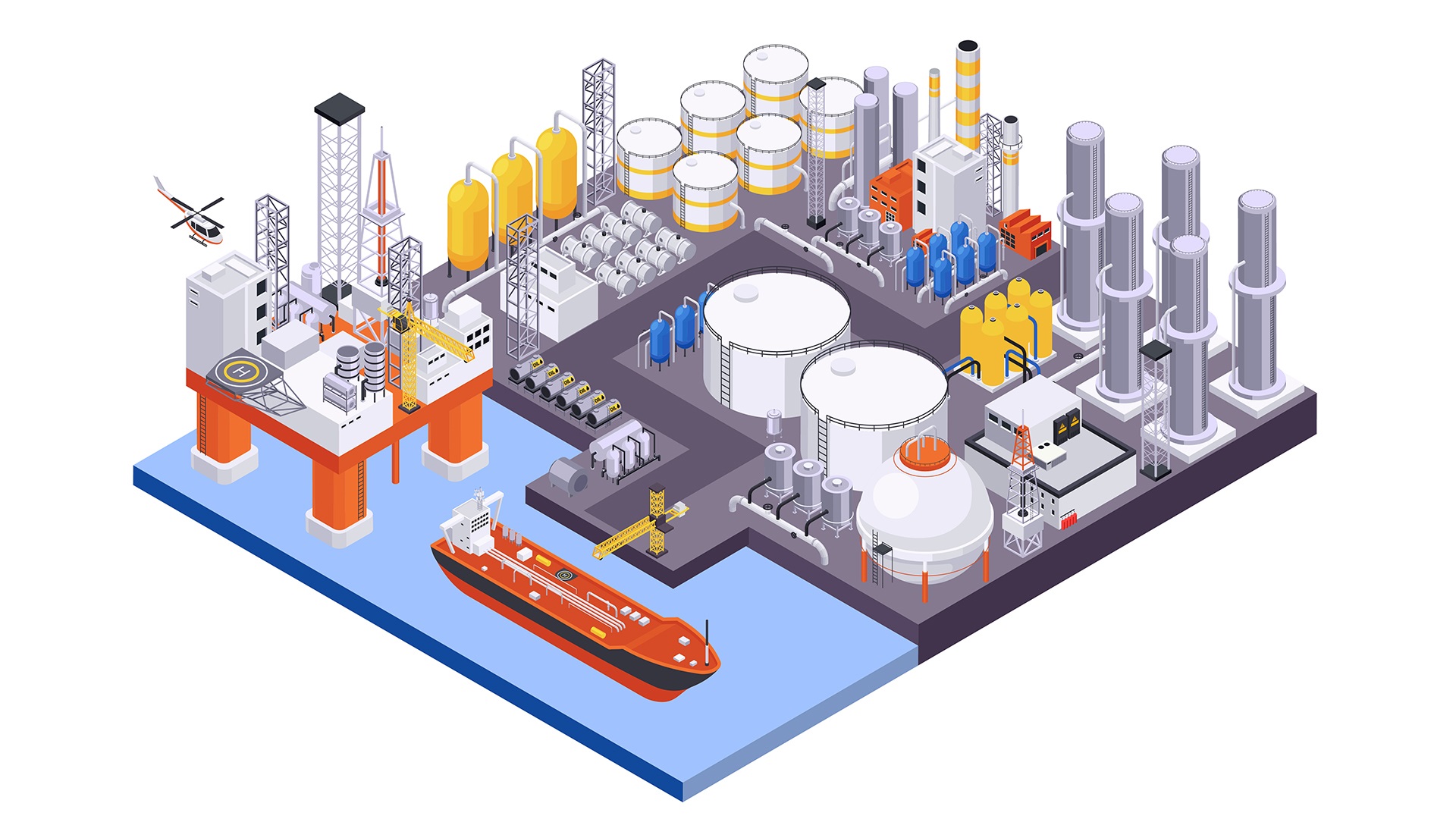

When it comes to accurate measurement, effective production deferment, and increased integrated production planning, the oil and gas industry has a difficulty. This training will teach professionals how to overcome these obstacles and provide improved surface manufacturing operations facilities.

What are surface facilities in the oil and gas industry?

Most people in the oil and gas business undertake normal activities and operations without evaluating and adhering to standard and needed practices. The primary function of any work facility is to separate the Well stream into oil, gas, and water and then market or dispose of these products in an environmentally friendly manner. The separator equipment is in charge of separating the gas from the liquids while efficiently separating the free water from the oil. The procedure is known as surface manufacturing operations.

This course will teach participants how to establish requirements for production operations facilities and promote safe practices in oil and gas production operations. Some of the issues that gas and oil production facilities confront include inadequate metering equipment and systems, as well as improper process allocation. It also involves a poor or non-existent deferment administration method. When these difficulties are not properly addressed, they may simply result in inconsistent oil and gas production, which in turn may result in unpredictable business cycles and field reserve estimation. This course is designed to teach the best practices and standards found around the world that should be followed.

What exactly are oil and gas production operations?

Production facilities must be capable of measuring various kinds of crude oil and collecting samples of accessible crude oil. The accommodation can be mechanized using an automation tool and a calibrated tank with a measuring gauging. Water disposal is also significant because there are rules that govern water disposal. Participants in this course will be able to learn all of these strategies as well as how to implement those using modern tools and technology.

Introduction

The “Oil and Gas Surface Production Operations Facilities Training” curriculum welcomes you. This thorough course is designed to provide you the knowledge and skills you need to succeed in the crucial field of oil and gas surface production operations. Whether you are new to the business or want to expand your knowledge, this program will provide you the tools you need to negotiate the complexity of upstream oil and gas facilities.

Oil and gas production facilities are at the cutting edge of the energy business, extracting, processing, and transporting hydrocarbons from the earth to meet the world’s energy demands. This training program is intended to provide a thorough understanding of these facilities, with an emphasis on safety, efficiency, and environmental stewardship.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

We are excited to embark on this educational adventure with you. We will investigate best practices in oil and gas surface production operations together, providing you with the information and skills required to manage these facilities efficiently, responsibly, and safely. Let us go on the path to excellence in oil and gas plant operations.

Learning Objectives

Upon completing Certificate in Oil and Gas Surface Production Operations Facilities, participants will be able to:

- Examine many aspects of surface flowing well situations with the goal of optimizing the production process.

- Encourage a safe and risk-free manufacturing process.

- Understand and describe in detail the basic layout of any existing upstream generating facility and the primary purpose of its major equipment.

- Describe a complete facility design by explicitly describing and outlining the requirements for treating and separating generated oil.

- Possess the ability to plan, design, and manage routine operations maintenance work.

- Control site activities and control while maintaining safe operations through the use of appropriate work practices.

- Recognize and comprehend what to look out for in manufacturing operations practice.

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Project-based learning

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

Training Medium

This Certificate in Oil and Gas Surface Production Operations Facilities training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- Define the main components and processes involved in surface oil and gas production operations.

- Describe any previous experience or knowledge you have in this subject.

- Name and briefly describe the many types of processing facilities used in the oil and gas business (for example, separation, compression, and dehydration).

- Describe any unique processing facilities with which you have worked.

- Describe the significance of safety in oil and gas operations.

- Please include any safety policies or processes with which you are familiar.

- Describe how environmental concerns are incorporated into surface oil and gas production processes.

- Mention any environmental laws or regulations that you are aware of.

Course Modules

This Certificate in Oil and Gas Surface Production Operations Facilities covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – Mechanical pressure equipment design

- Main design considerations

- Technical specifications for pressure equipment

Module 2 – Configuration of the system

- Gas dehydration Pumps Wellheads and manifolds

- Treatment and storage of oil

- Compressors

- Flowchart of the Process

- Platforms offshore

Module 3 – Surface oil and gas production principles

- Nomenclature for designating hydrocarbons

- Specific density and known liquid density

- The phase behavior

- System with multiple components

- Systems that go backwards

- Components of the system

Module 4 – Separation of oil and water in three phases

- Separators that operate horizontally

- Horizontal liquid “boot” separators

- Knockout in the open water

- Separators that are vertical

- Plates coalescing

- Flow of turbulent coalesces

Module 5 – Separator layout

- In horizontal separators, hall-full sizing is used.

- Constraints on gas capacity

- Time limits for retention

- Separation of oil droplets from water

- length from hem to hem

- Gas capacity limitation

- Time limit for retention

Module 6 – Surface manufacturing operations

- Integration of operations

- Tools for assisting with operations management

- Measuring devices

- Introduction to surface manufacturing procedures

- A summary of the well, reservoir, and facility management processes

Module 7 – Crude oil stability

- The Fundamentals of Crude Oil Stabilization

- Quick computations

- Considerations Regarding Equilibrium

- Stabilizer for reflux

- Stabilizer for cold feed

- Stabilizer for liquid hydrocarbons

Module 8 – created water treatment

- Disposal requirements and standards

- Water production characteristics

- Sulphate of barium and strontium

- Dispersion

- Separation by gravity

Module 9 – Integrated manufacturing

- Production workflow integration

- Integrated production business objectives

- Production concepts, both general and specific

- Strategy for developing a strong business strategy

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- After completing the course, summarize the essential components and procedures involved in oil and gas surface production operations.

- How has your knowledge of the subject evolved?

- List and explain the key types of oil and gas processing facilities that you learned about during the course.

- Give an example of a particular processing facility and its involvement in manufacturing activities.

- Describe the training’s safety policies and protocols and how they apply to oil and gas surface production operations.

- Share any course-related safety measures you intend to implement or improve.

- Describe how environmental concerns were incorporated into the training and how they relate to oil and gas activities.

- Mention any new insights you’ve received regarding environmental stewardship.

Lessons Learned

Safety is paramount: In oil and gas surface production operations, safety is non-negotiable. Participants should have learned that stringent safety protocols, regular equipment inspections, and a strong safety culture are critical for protecting employees and the environment.

Regulatory Compliance: Following environmental and safety rules is not just a legal need, but also a moral commitment. To minimize accidents and safeguard the environment, the training should emphasize the need of following to regulatory criteria.

Process Optimization: The training should emphasize the necessity of constantly optimizing production processes in order to improve efficiency, reduce costs, and reduce environmental effect.

Environmental Responsibility: Environmental stewardship is essential in the oil and gas business. Participants must comprehend the importance of reducing environmental effect, whether through spill avoidance or waste management.