Synchronous Oil & Gas Operation & Maintenance Elite

Course overview

The Synchronous Oil and Gas Operation & Maintenance Training are pleased to welcome you. This thorough course is created to give you the information and abilities required to succeed in the challenging and dynamic area of oil and gas operations and maintenance. This program will give you insightful knowledge and useful experience, whether you are already employed in the business or hoping to break into it.

Each module of the training is divided into a different area of oil and gas operations and maintenance. To put your knowledge and abilities to use in a practical way, you will participate in lectures, practical exercises, case studies, and discussions.

Assessments include of tests, homework assignments, practical exercises, and a final project to gauge your learning and development. These tests measure your competence and serve to reinforce your learning.

Maintenance technicians, engineers, supervisors, and anybody else interested in expanding their understanding of oil and gas operations and maintenance should attend this course. It is also appropriate for individuals already employed in the oil and gas industry as well as those looking to break into the sector.

Participant’s path to a fulfilling and demanding career in the oil and gas sector begins with the Synchronous Oil and Gas Operation & Maintenance Training. It gives you the knowledge and abilities necessary to succeed in this crucial industry, where environmental responsibility, effectiveness, and safety are of utmost importance. Together, let’s start this educational journey to get you ready for success in the oil and gas operations and maintenance industry.

Introduction

A unique training program called Synchronous Oil and Gas Operation & Maintenance Training was created to give people the knowledge, abilities, and competences they need to succeed in the oil and gas sector, particularly in the fields of operations and maintenance. Usually, educational institutions, vocational training facilities, or businesses in the oil and gas industry provide this extensive training program.

For people who want to succeed in the oil and gas sector, where successful and responsible operations and maintenance are essential for success and safety, this training program is a great resource.

We are The Training Bee, a global training and education firm providing services in many countries. With our highly specialized programs and training sessions, we are experts in capacity building and talent development solutions for people and companies.

Learning Objectives

Upon completing Synchronous Oil and Gas Operation & Maintenance Training, participants will be able to:

- Recognize the parts and operations of an oil and gas facility.

- Put safety and adherence to HSE requirements first.

- Use tactics for predictive and preventative maintenance.

- Plan and schedule maintenance tasks effectively.

- Recognize and address equipment malfunctions.

- Encourage operational environmental stewardship.

- Automate and analyze data using technology.

- Improve your teamwork and communication abilities.

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Project-based learning

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

Training Medium

This Synchronous Oil and Gas Operation & Maintenance Training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- How long have you worked in operations and maintenance, and what is your present position in the oil and gas sector?

- What are the essential elements and jobs performed by a typical oil and gas production facility?

- What are some of the most important safety laws or guidelines that are relevant to oil and gas activities and how well-versed are you in them?

- Do you have any formal training or qualifications in oil and gas maintenance and operations? If so, kindly give further information.

- What are some typical maintenance issues you’ve come across in the past, and how did you handle them?

- Describe a time when you had to intervene in a safety or emergency situation at an oil and gas site.

Course Modules

This Synchronous Oil and Gas Operation & Maintenance Training cover the following topics for understanding the essentials of the Agile Workplace:

Module 1 – Oil and Gas Operations Overview

- A description of the oil and gas sector.

- Oil and gas facility types.

- Environmental and safety regulations are very important.

- Important positions and duties in operations and maintenance

Module 2 – HSE practices: Health, Safety, and Environmental

- HSE guidelines and observance

- Identification of risks and risk assessment

- Strategies and procedures for safety

- Plans for emergency action and evacuation

- Measures to protect the environment

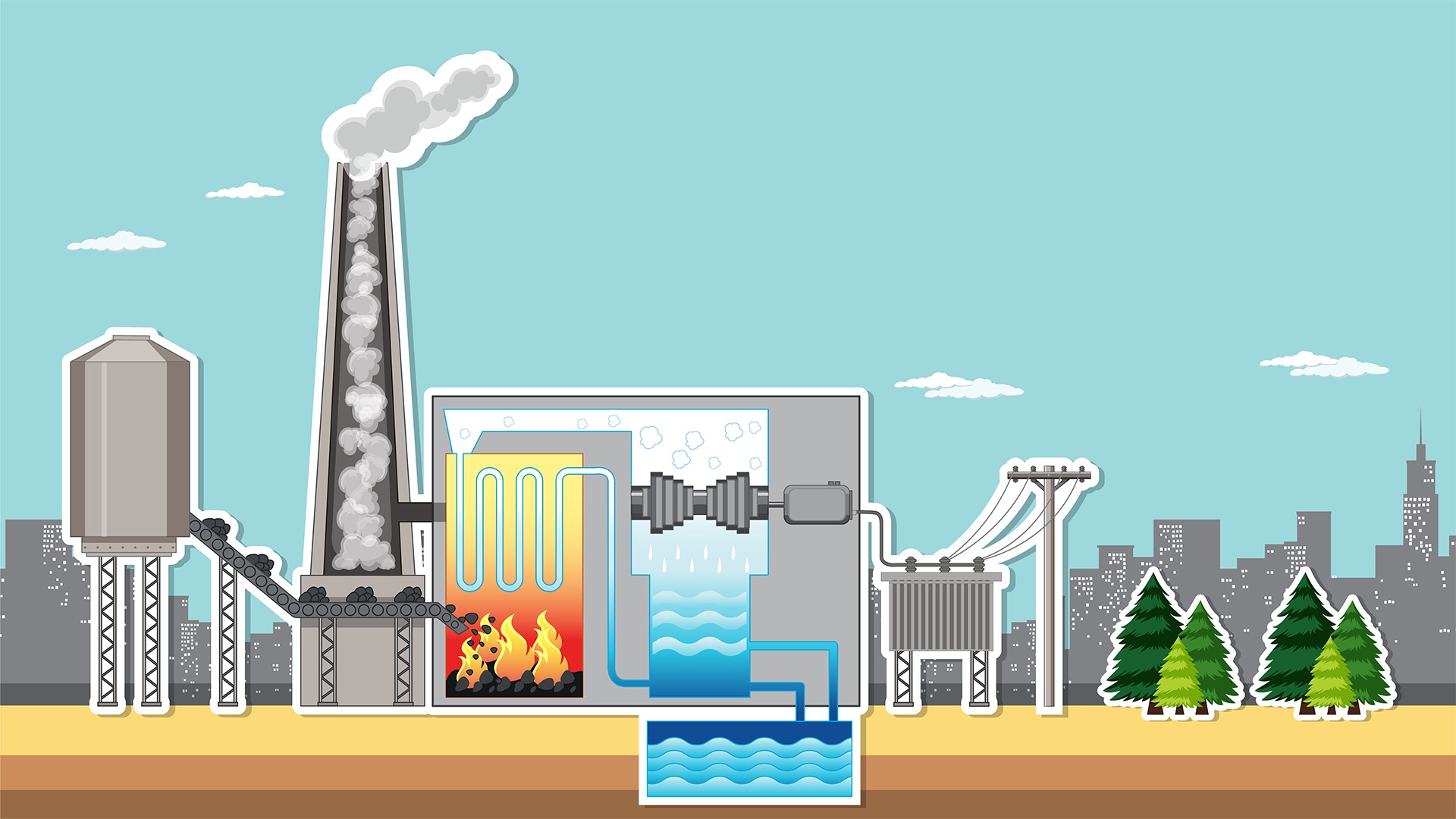

Module 3 – Overview of the Facilities and Equipment

- An introduction to the facilities and equipment used most frequently in oil and gas operations

- Overview of the systems for production, processing, and distribution

- Important equipment parts and operations, including pumps, compressors, and valves

Module 4 – Activities and Control

- Methods for observing and controlling

- Initiation and termination processes

- Use of safe procedures

- Recognizing abnormal operational circumstances

- Managing crises and alerts

Module 5 – Maintenance Techniques

- Preventive maintenance contrasts with remedial maintenance.

- Predictive maintenance methods, such as thermography and vibration analysis

- Scheduling and planning for maintenance

- Asset optimization and management

Module 6 – Inspection and testing of equipment

- Inspection techniques

- Procedures for non-destructive testing (NDT)

- Assessment of the dependability and integrity of equipment

- Documentation and reporting

Module 7 – Maintenance Workplace Safety

- Permits for safe work and isolation protocols

- Getting into small spaces and rescue methods

- Procedures for lockout / tag out (LOTO)

- Standards for personal protective equipment (PPE)

Module 8 – Identifying and fixing problems

- Recognizing typical problems and failures

- Methods for root cause analysis (RCA)

- Creating solutions and remedial measures

- Processes of continuous improvement

Module 9 – Collaboration and coordination

- Communication that works well in operations and maintenance

- Group effort and cooperation

- Settling disputes

- Reporting occurrences and close calls

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- Describe the main elements and purposes of a standard oil and gas production facility. Give instances to support your knowledge.

- What role do safety laws and standards play in oil and gas production and maintenance? How do these rules support effective and safe operations?

- Describe how preventive maintenance helps the oil and gas industry maintain the durability and dependability of equipment. Give some instances of preventive maintenance techniques.

- Describe the idea of preventative maintenance and how oil and gas facilities can use it. Give an example of when predictive maintenance would be beneficial.

- Give a general description of the planning and scheduling procedure for maintenance. How can good planning help in reducing downtime and maximizing maintenance tasks?

Lessons Learned

The most important lesson is that safety is of the utmost importance when operating and maintaining oil and gas facilities. Participants are aware that in order to avoid accidents, protect people and the environment, safety procedures and practices must always come first.

Regulation Compliance: Participants are aware of how important it is to follow all applicable environmental, health, and safety laws. In addition to being legally required, adherence to these criteria is also morally required in order to protect ecosystems and human lives.

The Key is Preventive Maintenance The instruction emphasizes the crucial part preventive maintenance plays in preserving equipment reliability and reducing downtime. Preventative actions cut expenses and lower the possibility of unanticipated shutdowns.

Efficiency through Predictive Maintenance: The use of predictive maintenance approaches is emerging as a useful tool for maintenance efficiency. Participants discover how to optimize maintenance schedules by anticipating equipment faults before they happen.

Optimized Maintenance Planning: For minimizing disruptions and extending asset lifespan, effective maintenance planning and scheduling are essential. Participants are aware of the challenges involved in effectively planning and scheduling maintenance tasks.

Environmental Stewardship: The course emphasizes the oil and gas sector’s obligation to safeguard the environment. Participants develop a greater understanding of environmentally friendly activities and impact reduction.