The Ultimate Oil Refinery Entrepreneur

Course overview

What responsibilities does an operations manager have?

Determining and analyzing oil refining activities as well as studying refinery operations fall within the purview of the oil refinery operation manager.

What is the operation of a refinery?

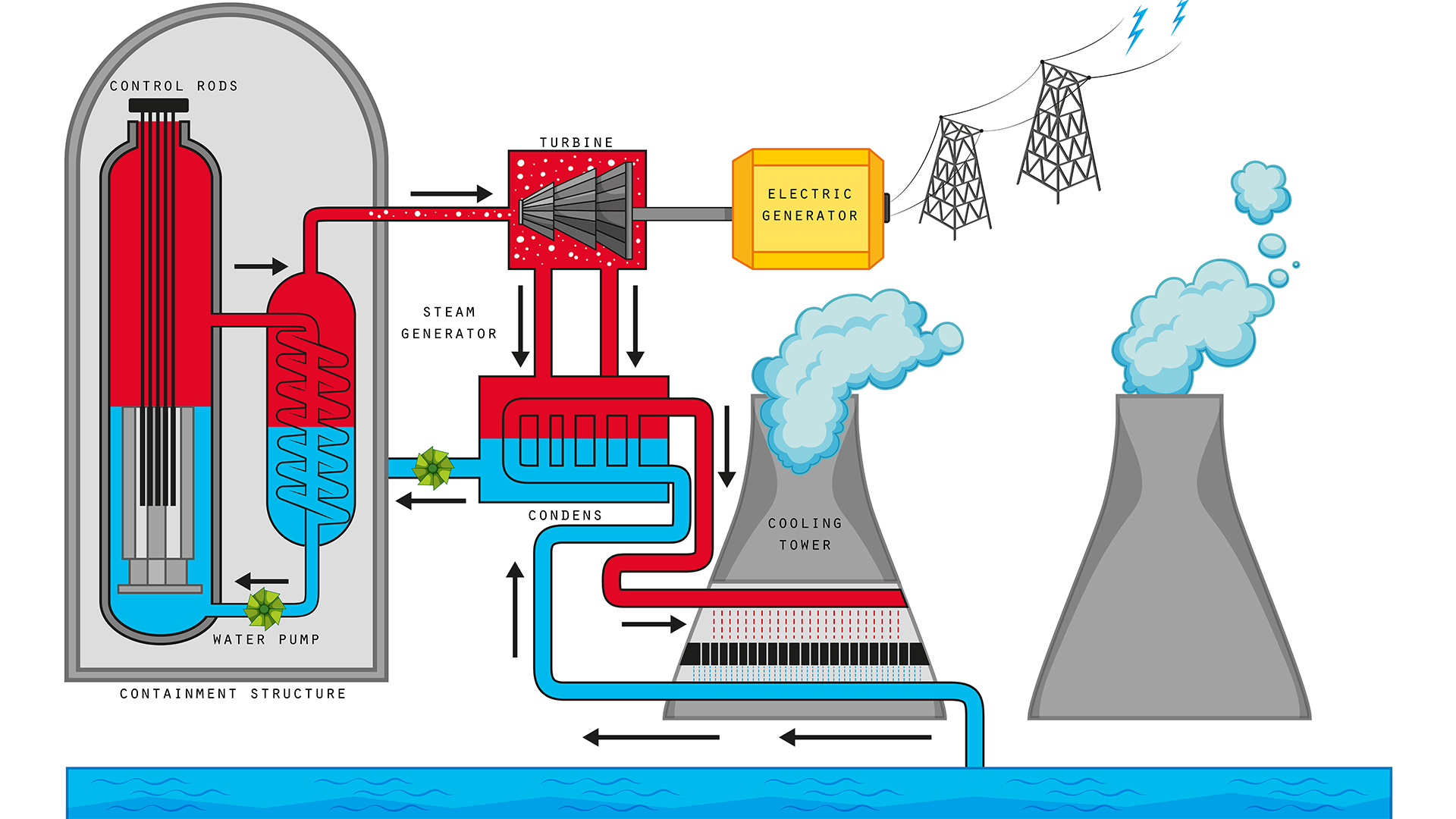

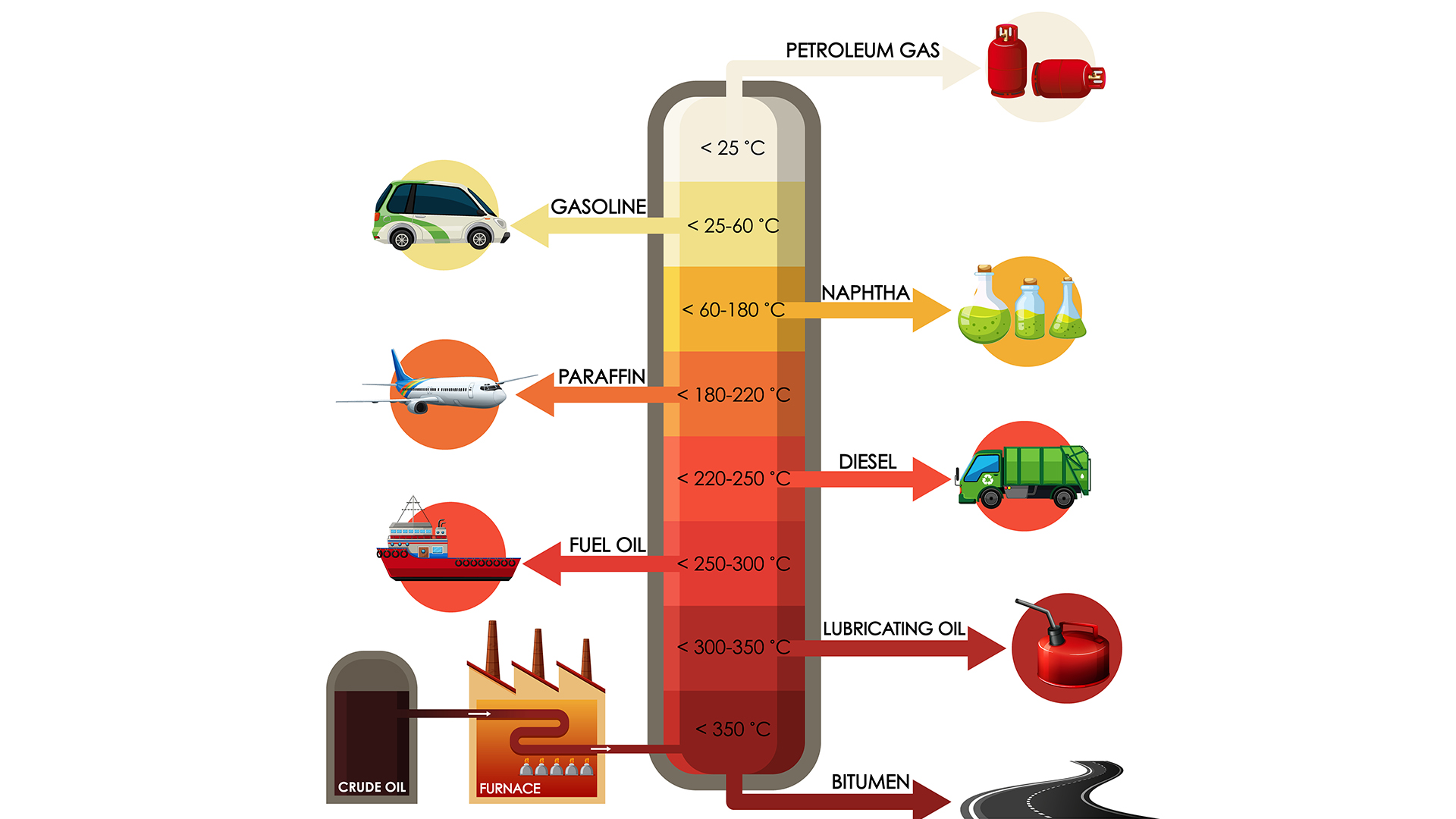

The crude oil used in petrochemical industries is processed to produce petroleum products. Wastewater must be reused and the oil industry must be used properly and efficiently. Electrical, mechanical, and thermal energy are all used in plants. Electric motors, transformers, boilers, compressors, blowers, chillers, processing machines, and other equipment are used in it. These devices function under diverse circumstances.

Participants will gain the knowledge and skills necessary to comprehend how an oil refinery operates and converts crude oil into petroleum products by taking this course on its operations. The primary focus of this course will be on the methods used to generate energy, heat, pave roads, and power vehicles. Effectively separating crude oil into its constituent parts to create new products is the process of refining. Everything from oil production and generation to oil transportation and management is covered in the course on oil refinery operations, including system analysis.

Participants have the chance to improve your abilities and support your organization in managing oil refinery operations with the aid of this Training Bee course.

Introduction

A thorough educational program called “training in oil refinery operations” is intended to give participants the information, abilities, and know-how needed to operate safely and successfully in the intricate and vital industry of oil refining. The complex industrial facilities known as oil refineries are in charge of processing crude oil into a variety of valuable products, including jet fuel, gasoline, diesel fuel, and different petrochemicals.

Investing in training for oil refinery operations contributes to the industry’s sustainability, efficiency, and safety in addition to helping individuals advance their careers. It is essential to guarantee that experts in this industry are equipped to handle the special opportunities and problems that come with working in one of the most important sectors of the global economy.

We are The Training Bee, a global training and education firm providing services in many countries. We are specialized in capacity building and talent development solutions for individuals and organizations, with our highly customized programs and training sessions.

Learning Objectives

Upon completing Mini MBA: Oil Refinery Operations, participants will be able to:

- Gaining knowledge about every facet of oil refinery operations

- To impart information and abilities for professional management in the oil refinery business

- To give an overview of the numerous crucial steps involved in oil refining

- Possess in-depth understanding of the managerial aspects of oil refining

- Analysis of system parameters and methods for oil refining operations

- To determine methods for producing different types of oil components

- The capacity for and likelihood of using effective devices

- The required understanding of regulations with laws and regulations

Our Unique Training Methodology

This interactive course comprises the following training methods:

- Journaling – This consists of setting a timer and letting your thoughts flow, unedited and unscripted recording events, ideas, and thoughts over a while, related to the topic.

- Social learning – Information and expertise exchanged amongst peers via computer-based technologies and interactive conversations including Blogging, instant messaging, and forums for debate in groups.

- Project-based learning

- Mind mapping and brainstorming – A session will be carried out between participants to uncover unique ideas, thoughts, and opinions having a quality discussion.

- Interactive sessions – The course will use informative lectures to introduce key concepts and theories related to the topic.

- Presentations – Participants will be presented with multimedia tools such as videos and graphics to enhance learning. These will be delivered engagingly and interactively.

Training Medium

This Mini MBA: Oil Refinery Operations training is designed in a way that it can be delivered face-to-face and virtually.

Course Duration

This training is versatile in its delivery. The training can be delivered as a full-fledged 40-hour training program or a 15- hours crash course covering 5 hours of content each day over 3 days

Pre-course Assessment

Before you enroll in this course all we wanted to know is your exact mindset and your way of thinking.

For that, we have designed this questionnaire attached below.

- What is an oil refinery’s main objective?

- What are the primary categories of crude oil processing units found in refineries?

- Describe the fundamental processes that are used to refine crude oil into its many products.

- In an oil refinery, which safety precautions are crucial, and why?

- How does distillation function and what role does it play in the refining process?

- Describe the idea of hydrocarbon cracking and how the refinery process uses it.

- In oil refinery, how is the quality of refined products monitored and controlled?

- What typical environmental issues and rules are connected to oil refineries?

- Provide an illustration of a managed byproduct that is created during the refining process.

Course Modules

This Mini MBA: Oil Refinery Operations covers the following topics for understanding the essentials of the Agile Workplace:

Module 1 – An outline of the procedure for separating oil

- Overview of petrochemical plants and refineries

- Distilleries procedure

- Distillation methods

- Airborne Distillation

- Distillation by vacuum

- Processing of gas

Module 2 – Process of converting petroleum

- Reforming

- Alkylation

- Polymerization

- Isomerization

- Coking

- Vis breaking

Module 3 – Procedures for treating petroleum

- Hydro desulfurization

- Hydro-processing artificial sweeteners

- Removal of acid gas DE asphalting

Module 4 – Fundamentals of management

- Arranging, coordinating, managing, controlling, and scheduling

- Drive and tactical preparation

- HR and maintenance management

Module 5 – Handling of products and feedstock

- Keeping oil products stored

- Operations for blending

- Loading procedures

- Handling and feedstock management

Module 6 – Supplementary amenities

- Boiler and operation management research

- Wastewater handling

- Production and usage of hydrogen

- Sulfur recovery facility and its functioning

Module 7 – Laws, rules, and regulations

- Rules governing the refining of oil

- Laws pertaining to the chemical industry in different nations

- Environmental issues and regulations

Module 8 – Treatment of waste and wastewater

- Types of trash produced by oil refineries

- Disposal of waste system

- Waste handling and activities

Module 9 – Pollution and upkeep supervision

- Pollution as well as its effects

- Technologies for managing and preventing pollution

- No liquid outflow

- Management of failure and reliability

- Device maintenance administration

Post-course Assessment

Participants need to complete an assessment post-course completion so our mentors will get to know their understanding of the course. A mentor will also have interrogative conversations with participants and provide valuable feedback.

- Which training program concepts or abilities did you find most useful?

- Did the course fulfill your expectations? Please elaborate.

- In what ways has this training improved your comprehension of safety procedures and oil refinery operations?

- Did you come across any particular subjects or fields that you found very difficult or that you would like to learn more about in the future?

- Did the training sufficiently cover the environmental laws and safety precautions pertaining to operating an oil refinery?

- Have you gained the information and abilities required to function well in an oil refinery setting?

- In your present position or in your next job, how do you intend to use the knowledge you’ve gained?

- Did the handouts, presentations, and internet sites that were used as training materials help you learn the material?

Lessons Learned

The paramount importance of safety in oil refinery operations is the most crucial lesson that can be taught. A thorough awareness of safety procedures, the application of personal protective equipment (PPE), and the necessity of always putting safety first should have been imparted to participants.

Participants should have gained a thorough understanding of the intricate procedures involved in converting crude oil into a variety of products. This covers unit activities such as cracking and distillation.

Environmental Responsibilities: The need of following best practices and environmental rules in oil refining should have been underlined in the training. The effects of refinery activities on the environment and the mitigation strategies in place should be understood by all participants.

Process Optimization: In order to increase productivity, cut waste, and improve product quality, participants must to have learned about how refinery operations are optimized.

Effective collaboration and communication are essential for working in an oil refinery. The ability to communicate vital information and work well with others should have been acquired by the participants.

Adapting to Difficulties: Participants ought to have gained knowledge on how to deal with unanticipated difficulties and crises that could arise in an oil refinery. This covers handling unexpected circumstances, accidents, and equipment breakdowns.

Continuous Learning: Since oil refinery operations are always changing, participants should be aware of the value of continuing their education and staying current with technological advancements in the sector.